So, I had this idea that maybe I could thin out the top layer of my fused panels (so there would be less to cut through by draping the top layer over the base layers through slumping it over them during the firing. This didn't work at all, mostly because I need to practice drop slumping things, and I was being throughly unscientific by trying a bunch of things, all new to me, at once. In addition to thinking i might be able to thin the top layer out, I though it might thin unevenly to create a bit of a gradient if I slumped it from a different height on each side. So, I was being silly. Oh well. Here's the program, adapted from the creative ceramics eu drop ring slump program.

150C/H to 540C hold 0:00

15C/H to 660C hold 0:15

333C/H to 804C hold 0:10

AFAP to 482C hold 0:30

83C/H to 371C hold 0:00

AFAP to 50C end

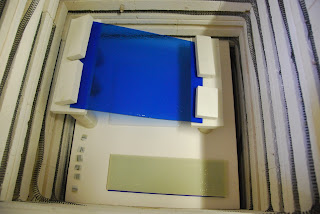

Everything fell over (evidently something was unbalanced, no?), but the bricks falling on top of the glass, actually made interesting indents, so, that might be something to think about... weighting fusing in the kiln to give it texture and different form.

Also, the largeish piece in the bottom right of the kiln still had largish bubbles, so I need to think about ways to reduce bubbles in my larger flat fusing in the future.